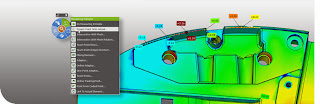

The 3D laser scanners provide accurate scans with detailed

resolution at high speeds. ATOS delivers three-dimensional measurement data and

analysis for industrial components such as sheet metal parts, tools and dies,

turbine blades, prototypes, injection molded parts, castings, and more. Instead

of measuring single points or with a laser, ATOS captures an object‘s full

surface geometry and primitives precisely in a dense point cloud or polygon

mesh.

ATOS is

widely utilized in various industries, and can measure different object sizes,

surface finishes, and shape complexities:

•

Highly accurate 3D

measurements

•

Detailed, high-resolution

scans

•

Quick data collection

•

Advanced inspection

functionality

•

Complete dimensional analysis

•

Comprehensive reporting

Optical 3D

measuring technology and full-field surface measurement systems have become a

standard tool within virtually all industries. Engineered with the highest

quality, our measurement systems have proven to be an indispensable asset for

quality control in modern product development and production process chains.

•

Optimize design and

manufacturing processes

•

Complete standardized quality

control

•

Rapid full part inspection and

analysis

•

High-definition data for

reverse engineering

•

Accelerated return of

investment

•

Uniform quality standards for

producers and suppliers

With over 20 years of industrial experience, we are a solutions provider that integrates 3D measuring technology by partnering

directly with customers to improve product quality and workflows.